Where & Why Tungsten Heavy Alloy is Used

In most density-driven applications, tungsten alloy is the sole material you can use. Here’s where and why tungsten heavy alloy is employed.

WHAs (tungsten heavy alloys) are a type of two-phase composite made up of almost spherical tungsten particles embedded in a ductile matrix phase. It consists of lower melting point metals such nickel, iron, copper, and cobalt. WHA is used in various fields. WHA is typically employed in counterweights, inertial masses, radiation shielding, ordnance goods, and various other uses. Please search on the net for tungsten heavy alloy suppliers near me and connect with Agescan international for various applications that need great strength, density, and weight.

Where and Why Should WHA Be Used?

When thinking about WHAs, it’s vital to remember that the metals business is always improving. Modern WHA materials outperform in terms of performance, quality, and reliability compared to WHA materials made 30 years ago.

Many process variables, including raw materials, manufacturing conditions, and actual alloy composition, are why today’s WHAs outperform those of the past. The quality of the raw materials is widely available, including tungsten, iron, and nickel.

Closed-loop feedback systems for real-time quality control have been installed in the manufacturing cells where the powders are transported, pressed, and sintered. Copper is no longer present at substantial levels in today’s alloying formulations. Older versions had more copper, making them more susceptible to galvanic corrosion.

Why Should You Choose WHA?

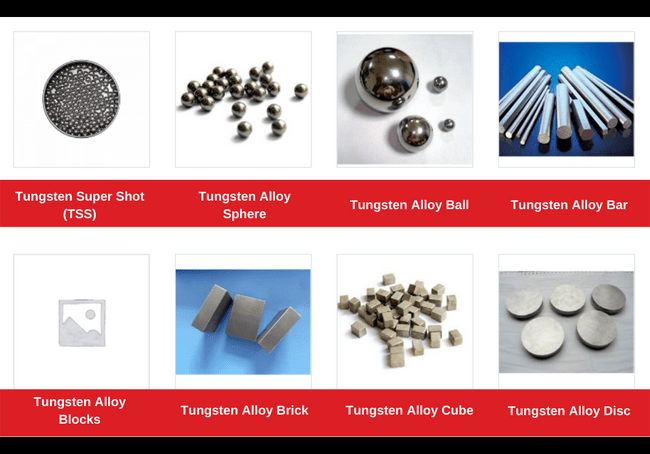

Tungsten heavy alloy is a less expensive option than pure tungsten, as it may be sintered straight to full density in the liquid phase without any extra processing. WHAs are now well-suited to a variety of applications. Powder metallurgy (P/M) is an old but still commonly used and upgraded industrial method that produces WHAs.

Various processes are utilized in the powder metallurgy to densify and alloy tungsten into conventional and unique shapes/parts. We at Agescan International are tungsten alloy manufacturers who produce sintered WHAs that feature a nonporous surface. Furthermore, bulk density in cross-sections is within a fraction of 100%.

Which is Better: Tungsten Heavy Alloy Or Alternatives?

Lead and Uranium are often poor alternatives due to their extreme toxicity to organic life. Lead is especially soft, with little to no tensile strength or stiffness, and is approximately 40% less dense than WHA. Tantalum has a density similar to tungsten, is ductile, and simple to deal with, yet it is prohibitively costly.

WHAs are a unique alloy solution that provides design engineers with various alternatives due to the flexibility of alloying content and material qualities.

Temperatures

Different types of tungsten heavy alloy, when subjected to temperatures beyond 500 °C, will significantly lose strength in any environment. Molybdenum or pure tungsten may be preferable options for higher-temperature applications. However, they will oxidize if they are not in hydrogen or inert gas.

Where is WHA Used?

Tungsten Heavy Alloy products are available as machinable blanks or finely machined components to client specifications and are utilized in various applications.

- Balance turbine, crankshaft, and helicopter rotor weights

- Weights for inertial damping on airplane control surfaces

- Aircraft, missiles, watercraft, and race vehicles all have different weights

- Penetrators for kinetic energy

- High-energy x-ray systems require radiation shielding, radioisotope canisters, and collimators in scientific, industrial, medical, and homeland security applications

- Boring bars and tool holders with low chatter and excellent rigidity for metalworking

- Instrument casings with a high density for downhole formation logging in oil/gas wells

- Weights for Vibration Dampening

Conclusion

This blog has included all the information about where and why tungsten heavy alloy usage occurs. We hope you found it to be useful. For more information about our tungsten alloys and other metals goods, visit our website. Agescan International is a prominent tungsten alloy supplier; don’t hesitate to contact us if you have any questions.

If you want to read the latest trending news for business category, then visit digibizner.com website today.